Products / Rapeseed drilling costs calculator / RSL Strip Till Drill

Winter Rapeseed Strip Till Drill RSL

Products / Rapeseed drilling costs calculator / RSL Strip Till Drill

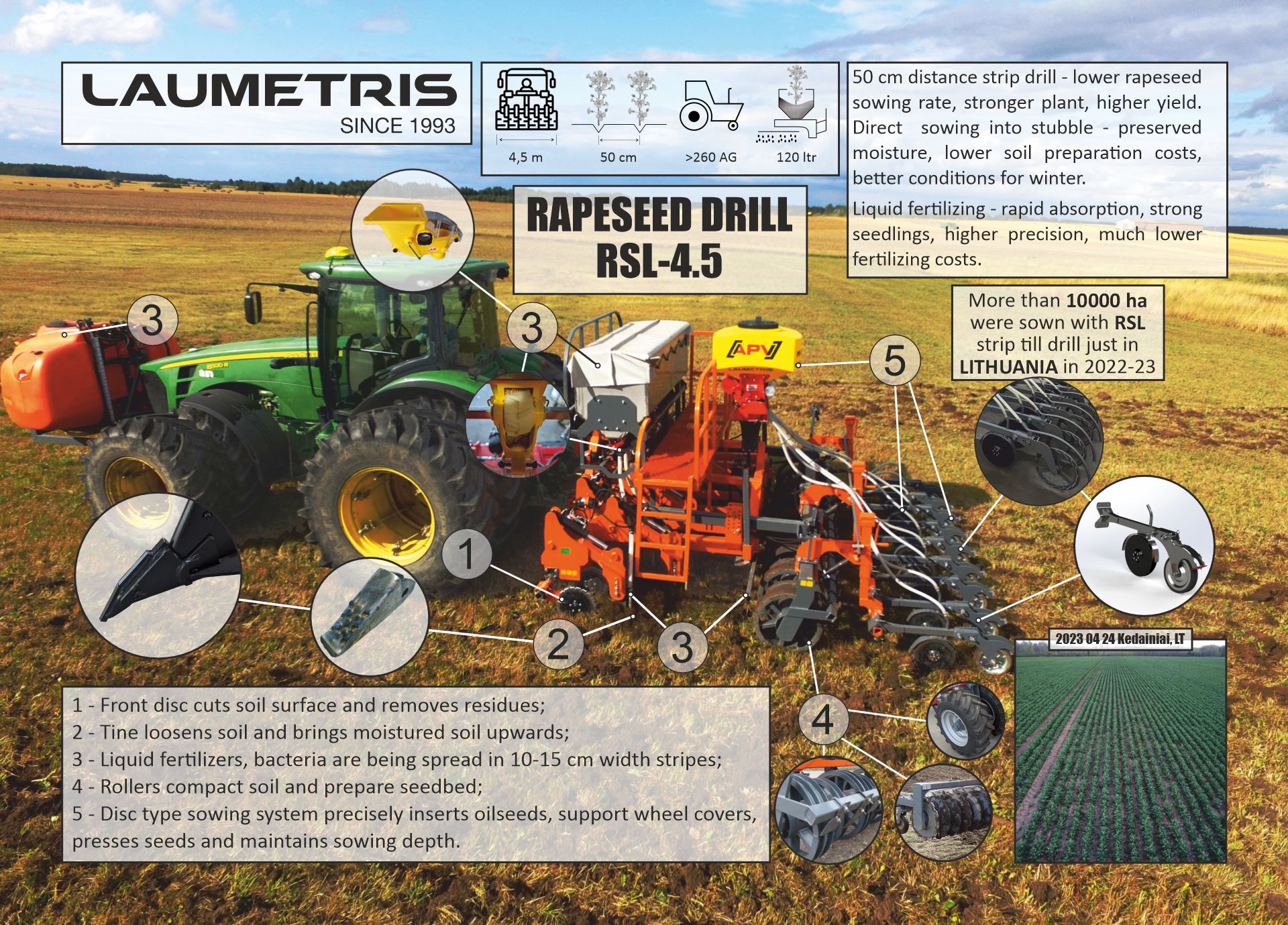

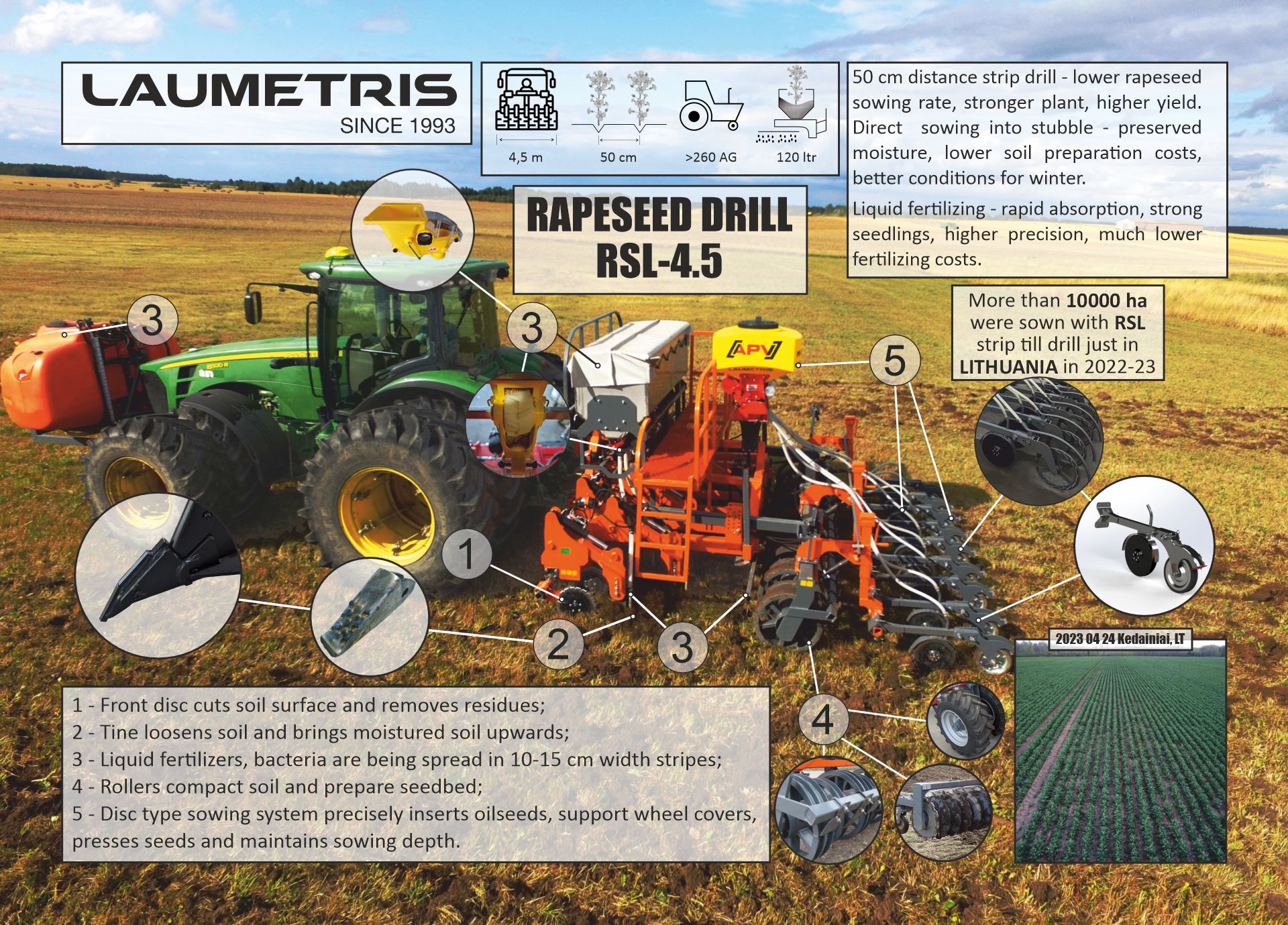

Growing of oilseed / rapeseed usually is a profitable crop even if yield is just average. Soil richness, seedbed preparation, selection of seed, fertilizers, plants protection agents are key factors impacting the end quality of crop and its yield. Every step from fields preparation to harvest means costs, the lower – the better (if yield stays the same or insignificantly lower). “Laumetris” concentrates on reducing costs of seedbed preparation and sowing process also on establishing of optimal conditions for seeds germination. All is set through Strip Till technology, which usually does not improve income / yield but highly reduces costs – improved profit astonishes every conventional farmer.

Every conventional farmer when harvest season is over hurries to ploughing or harrowing one‘s fields. With harrowing farmer mixes plant residues with soil and stimulates dropped seeds to germinate which leads to inevitable second harrowing before sowing of winter rapeseed. Ploughing on the other hand puts residues deep under the soil and, if moisture conditions are great, farmer may directly go with a sowing machinery. If moisture level is down additional cultivation or compaction with rollers is necessary. Both technologies: harrowing and ploughing, end up on few drives before sowing and another negative side effect is mineralization of stubble, which always extracts nitrogen from soil.

The first “Laumetris” subsoilers were manufactured back in the beginning of new millennium, over the time: countless tests and improvements, gained experience, ledto creation of RSL strip till drill, which offers the highest quality aggregate for soil loosening and winter rapeseed sowing. The key feature is Strip Till type drilling in width of 50 cm. Average costs per hectare of such drill is 38-45 Eur/ha. Easy to use Rapeseed drilling costs calculator enables everyone of you to analyze costs of your current drilling technology and compare with Laumetris RSL drilling costs. Link to the calculator:

| Model | RSL-2.5 | RSL-3.0 | RSL-3.5 | RSL-3.5T | RSL-4.0 | RSL-4.0T | RSL-4.5 | RSL-4.5T | RSL-5.5T |

|---|---|---|---|---|---|---|---|---|---|

| Type | mounted | trailed | mounted | trailed | mounted | trailed | |||

| Sowing width, m | 2,5 | 3,0 | 3,5 | 3,5 | 4,0 | 4,0 | 4,5 | 4,5 | 5,5 |

| Sowing depth, mm | 10-20 | ||||||||

| Tines operational depth, mm | up to 300 | ||||||||

| Tines, pcs | 5 | 6 | 7 | 7 | 9 | 9 | 9 | 9 | 11 |

| Row distance, mm | 500 | 444 | 500 | ||||||

| Tine type | straight flatliner tine | ||||||||

| Tines protection | hydro-pneumatic | ||||||||

| Wear points with carbide tiles | + | ||||||||

| Front cutting discs quantity, pcs | 5 | 6 | 7 | 7 | 9 | 9 | 9 | 9 | 11 |

| Precise sowing through discs, pcs | 5 | 6 | 7 | 7 | 9 | 9 | 9 | 9 | 11 |

| Roller type | 600 mm U type | wheels | U type | wheels | U type | wheels | |||

| APV pneumatic seeder | PS120 with automatic seeding rate control (7 pin cable for speed) | ||||||||

| Fertilizing system | mineral - 800 ltr / liquid - 1100 ltr | mineral - 1200 ltr / liquid - 1500 ltr | mineral - 2000 ltr / liquid - 1900 ltr | ||||||

| Transportation width, m | 2,95 | 3,05 | 3,5 | 3,5 | 3,85 | 3,85 | 4,4 | 4,4 | 4,0 |

| Mass, kg | 2600 | 2900 | 3200 | 3600 | 3650 | 4150 | 3750 | 4500 | 6000 |

| Min. tractor power, HP | 160-200 | 180-210 | 200-250 | 180-250 | 265-315 | 250-300 | 280-320 | 260-310 | 350-400 |

| Additional equipment | |||||||||

| Radar or GPS sensor for APV seeder | + | ||||||||

| Liquid fertilizing system, ltr | 1100 | 1500 | 2000 | ||||||

| Mineral fertilizing system, ltr | 800 | 1200 | 2000 | ||||||

| Automatic rate control for liquid / mineral fert. system through APV control box | + | ||||||||

| APV Antislug chemical speader | MDP 40 / KS 40 | ||||||||

| Special steel pressing wheels for seeds | + | ||||||||

| Trailed version | + | standard | + | standard | + | standard | |||

| Additional wheel type roller, dia. 750 mm | + | ||||||||

Technical details listed in the table are preliminary.